Background When builder Josh McDowell undertook an addition to an existing house, he had a clear vision: maintain the charm and style of the original structure without the hassle and expense of ordering new knives to match the existing mouldings. This approach allowed McDowell & Jordan to avoid labor and added expense. Challenge The key challenge was to seamlessly integrate new beams into an addition while ensuring the new trim profiles matched the original home’s architectural style. This required selecting profiles that would create a harmonious flow between the old and new structures. Solution To meet this challenge, ITC Millwork representative Jenny Taylor carefully selected a series of trim profiles that closely resembled the original aesthetic. Leveraging Koetter Woodworking's EnvisionIT design tool, Jenny created detailed drawings to visualize the proposed profiles. This step ensured all parties were on the same page before moving forward. Implementation & Outcome The drawings were presented to the client for approval and put into action, resulting in a harmonious blend with the original house, preserving its unique character. By meticulously selecting compatible profiles and utilizing Koetter Woodworking’s EnvisionIT design tool for visualization, ITC Millwork ensured seamless integration of the new addition with the existing home. This approach satisfied the builder's desire for design continuity and avoided extensive and costly removal and replacement of the original architectural trim and details. Why Choose ITC Millwork?At ITC Millwork, we take pride in providing and tailoring solutions that respect and enhance existing structures. Our commitment to quality and precision ensures seamless integrations that blend with and preserve your project's charm while delivering exceptional value.

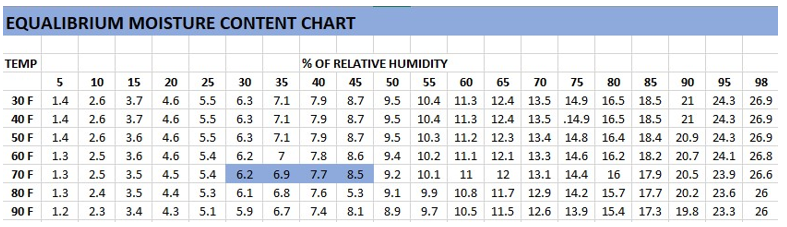

In the frenetic pace of constructing dream homes, the spotlight often gravitates towards cutting-edge appliances and extravagant finishes, captivating the homeowner's imagination. Yet, amidst the glitz and glamour, there exists an unsung hero that silently shapes the very essence of a home—the interior millwork. Architectural millwork and doors are not mere fixtures; they are the soul of a home, influencing its ambiance and character. The selection process of these crucial elements transcends mere aesthetics; it's a pivotal game-changer that can elevate your builds from ordinary to extraordinary. In this blog, we'll delve into the multifaceted aspects of mastering millwork selection, exploring the factors that contribute to the enduring impact of an exceptional interior millwork package.  Wood Species: The Heart of the Matter At the core of mastering millwork selection lies the choice of wood species. Each wood species brings unique qualities to the mix, influencing the interior space's aesthetics, durability, and overall feel. Consider the following aspects: - Durability: Different wood species exhibit varying levels of durability. Hardwoods are renowned for their resilience, making them ideal for high-traffic areas. - Selection and Customization: A vast array of wood species allows for diverse design possibilities. Consider the architectural style of the home and the client's preferences when selecting and customizing millwork. - Green and Sustainable Options: As environmental consciousness grows, opting for sustainably sourced or reclaimed wood can be a compelling choice. Ensure your millwork selections align with eco-friendly practices. Finishing Touches: Paint and Stain Adherence The longevity of millwork is heavily influenced by the quality of finishes applied. Consider: - Paint Adherence: Certain wood species may require specific primers or preparation to ensure optimal paint adherence. Choose materials that accommodate the desired paint finish. - Stain Adherence: If a natural wood finish is preferred, selecting a wood species that readily accepts stains is essential. Achieving the desired color and finish depends on the inherent characteristics of the chosen wood.

To aid in the nuanced process of mastering millwork selection, ITC Millwork presents a collaborative guide in partnership with Koetter Woodworking.

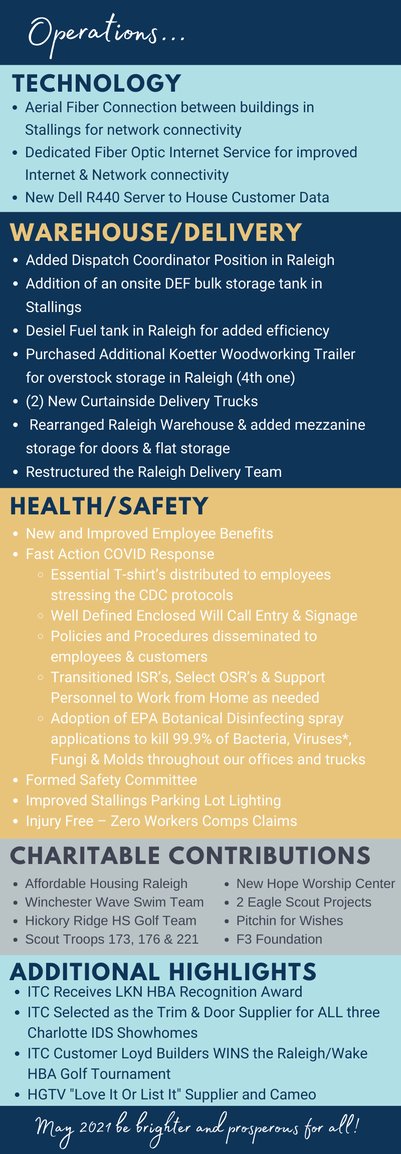

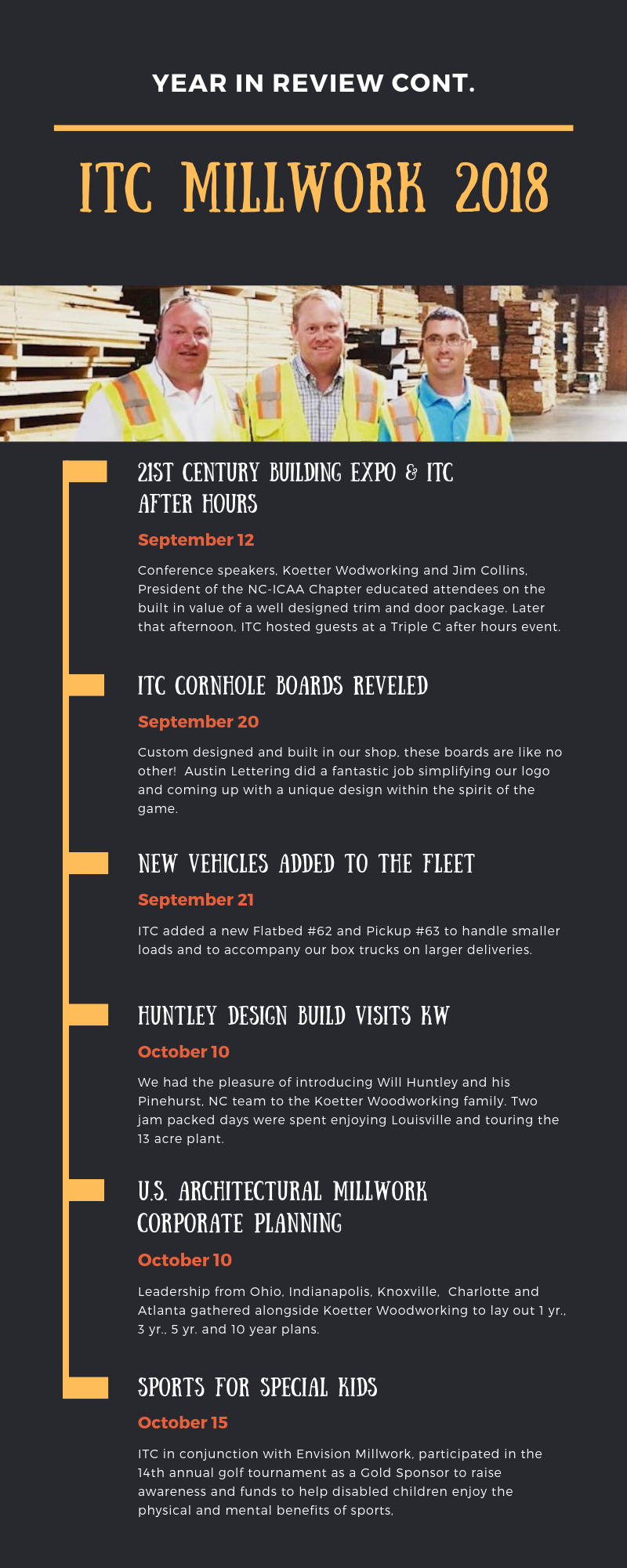

2020 was a year unlike any other, and one many of us would rather not see again. But in a year of unprecedented change, we adapted by approaching projects differently and grew not only as a company but also as individuals. As we worked to put together a list of achievements, we were pleasantly delighted to see the many good things that happened.

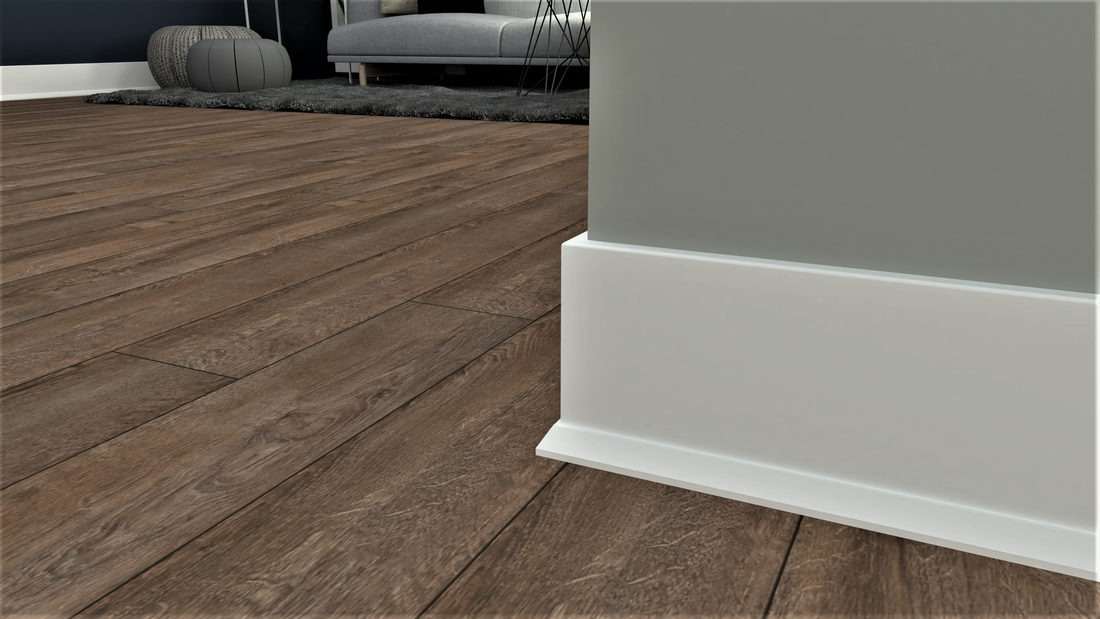

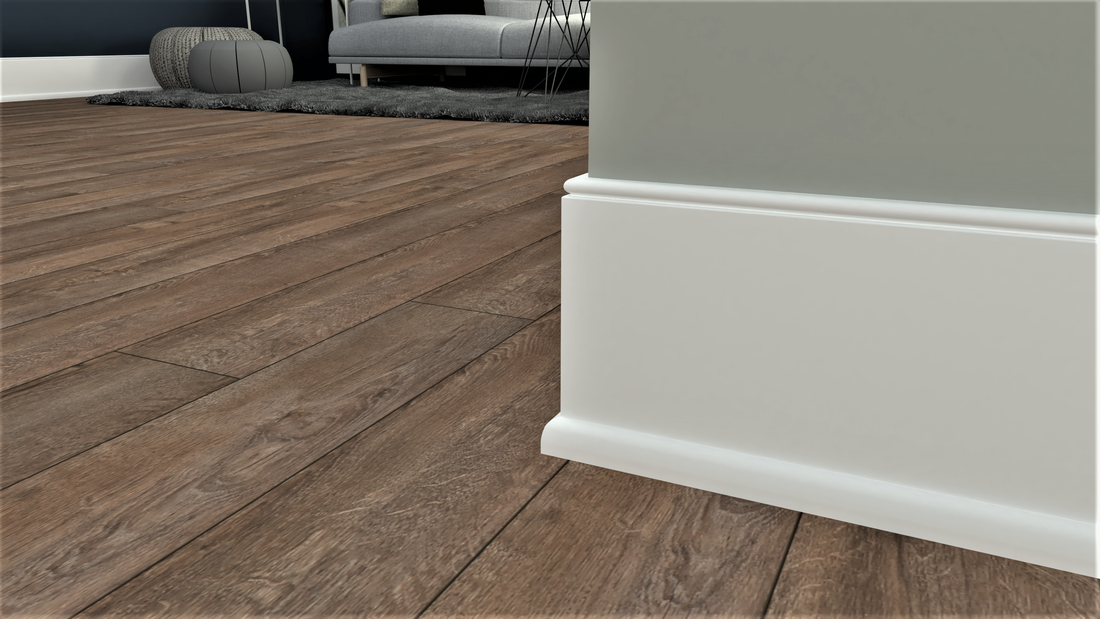

At ITC Millwork, we look forward to more silver lining moments and making 2021 even brighter and more prosperous for all! Is Shoe Mould really necessary or merely an afterthought?Obviously, without it, there is typically a gap between the trim and flooring, which is not only unattractive but makes it extremely easy for dirt and debris, including moisture, to build up under the base trim. Shoe mould is also one of the last items installed or even remotely considered because crown, casing, and base moulding tend to be the main focal points of a trim package. In its place, we commonly see commodity shoe tacked on, which often diminishes the overall appearance of its trim counterparts But what if shoe moulding were considered from the beginning? Beautiful crowning details! But this pretty room is sadly missing the shoe mould. To ensure architectural continuity and seamless transitions throughout the home, consider shoe moulding at the forefront of the trim design process versus the end. Whether you live in a house from centuries ago or are building a brand-new one, it is a critical element to achieving a well-designed trim package and "shoe matters." Based on your home's architectural style, consider using one of the following ITC Millwork stock profiles or consult with one of our millwork professionals for custom options. We look forward to assisting you with your next project. 2793 CWP paired with 4825 SHM

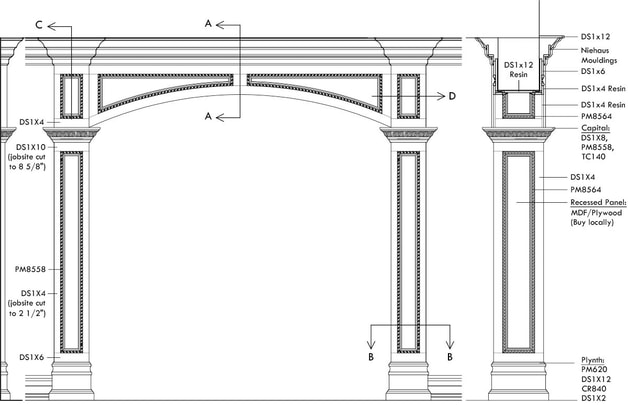

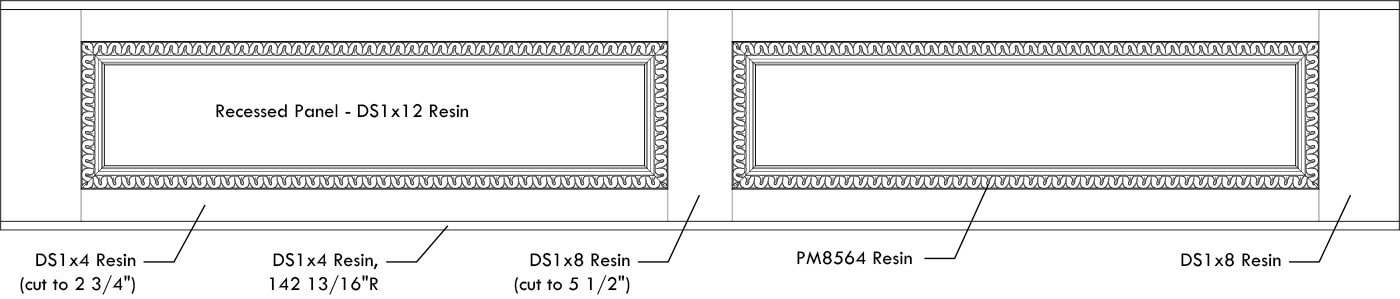

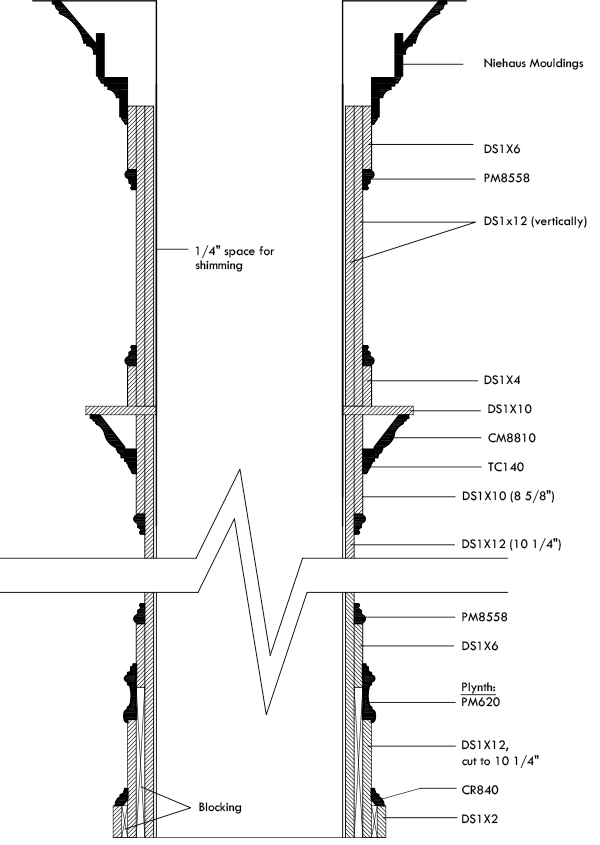

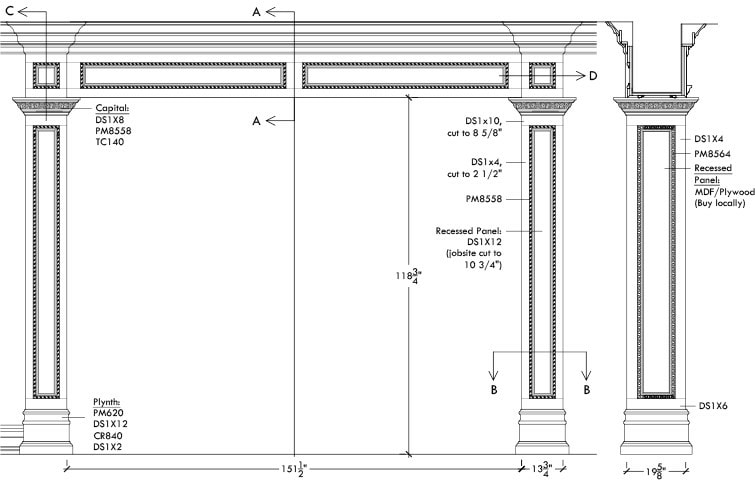

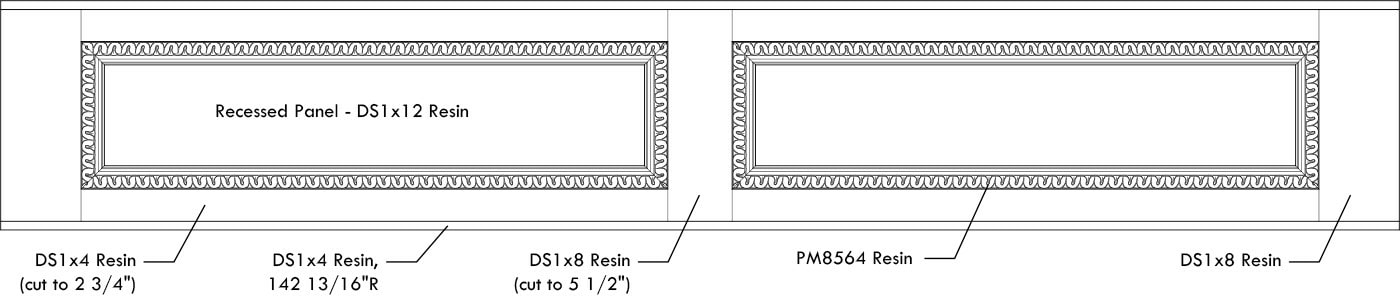

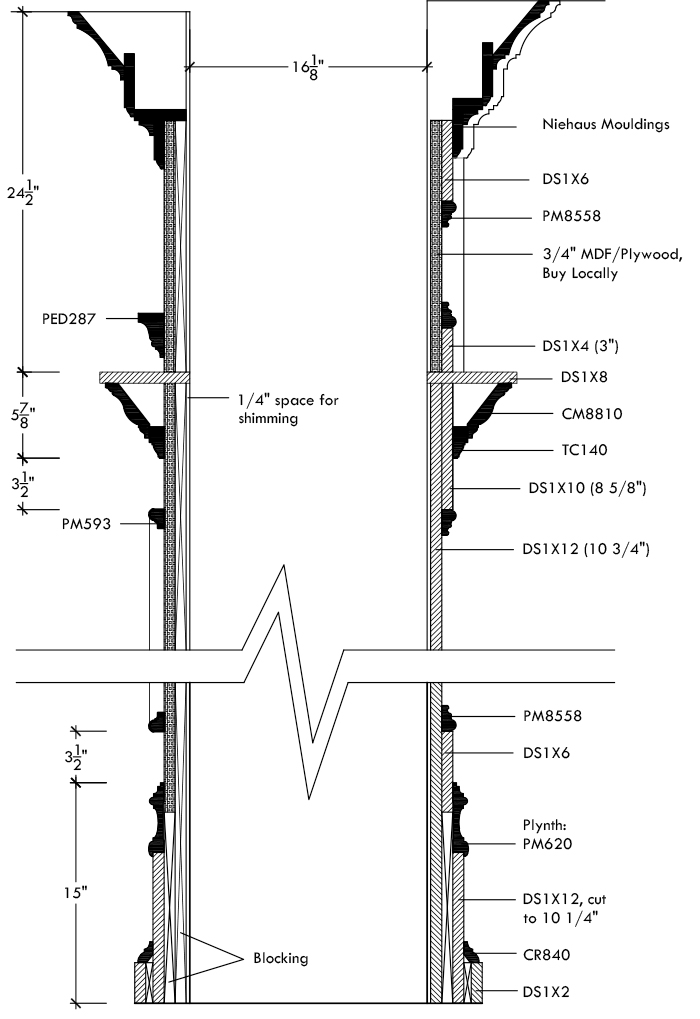

Guest Contributor: Coreena Harbison, Senior Designer White River Hardwoods There are so many design choices when it comes to doorways and openings. Straight, Arched, Smooth, Cased, Paneled, Columned, and in this instance, a combination: arched, paneled, with a square column. How do you successfully combine these different aesthetics? It takes a lot of forethought and careful planning to make sure you’ve accounted for all thicknesses, widths and any existing job-site conditions like outlets, switches and vents. Things can get especially tricky when dealing with curved mouldings, but we’ve broken down a recent project so you can see how all the individual parts come together to make a large and exceptional statement. White River’s Design Department worked from job-site dimensions to accommodate crown moulding and baseboards previously chosen by the builder. The width and height of the columns and panels needed to match on both openings and work with existing jambs.Front Vestibule OpeningUnderside of the JambSection CBecause the homeowner was painting and not staining, they chose to use a combination of MDF for the recessed panels and poplar for all the stiles, rails, and mouldings. Back Vestibule OpeningUnderside of the JambSection CYou can find these products and more at ITC Millwork.

|

AuthorThe ITC Millwork Blog is written by company thought leaders who have a strong pulse on the industry. They're expressive, skillful, and passionate about their jobs and our customers. Passion causes you to open your mouth when sometimes a whisper will do. Archives

July 2024

Categories

All

|

RSS Feed

RSS Feed